Some Ideas on Bulk Materials Handling You Should Know

Wiki Article

The smart Trick of Bulk Materials Handling That Nobody is Discussing

Table of ContentsBulk Materials Handling for BeginnersBulk Materials Handling Can Be Fun For AnyoneThe 5-Second Trick For Bulk Materials HandlingWhat Does Bulk Materials Handling Mean?The 5-Minute Rule for Bulk Materials Handling

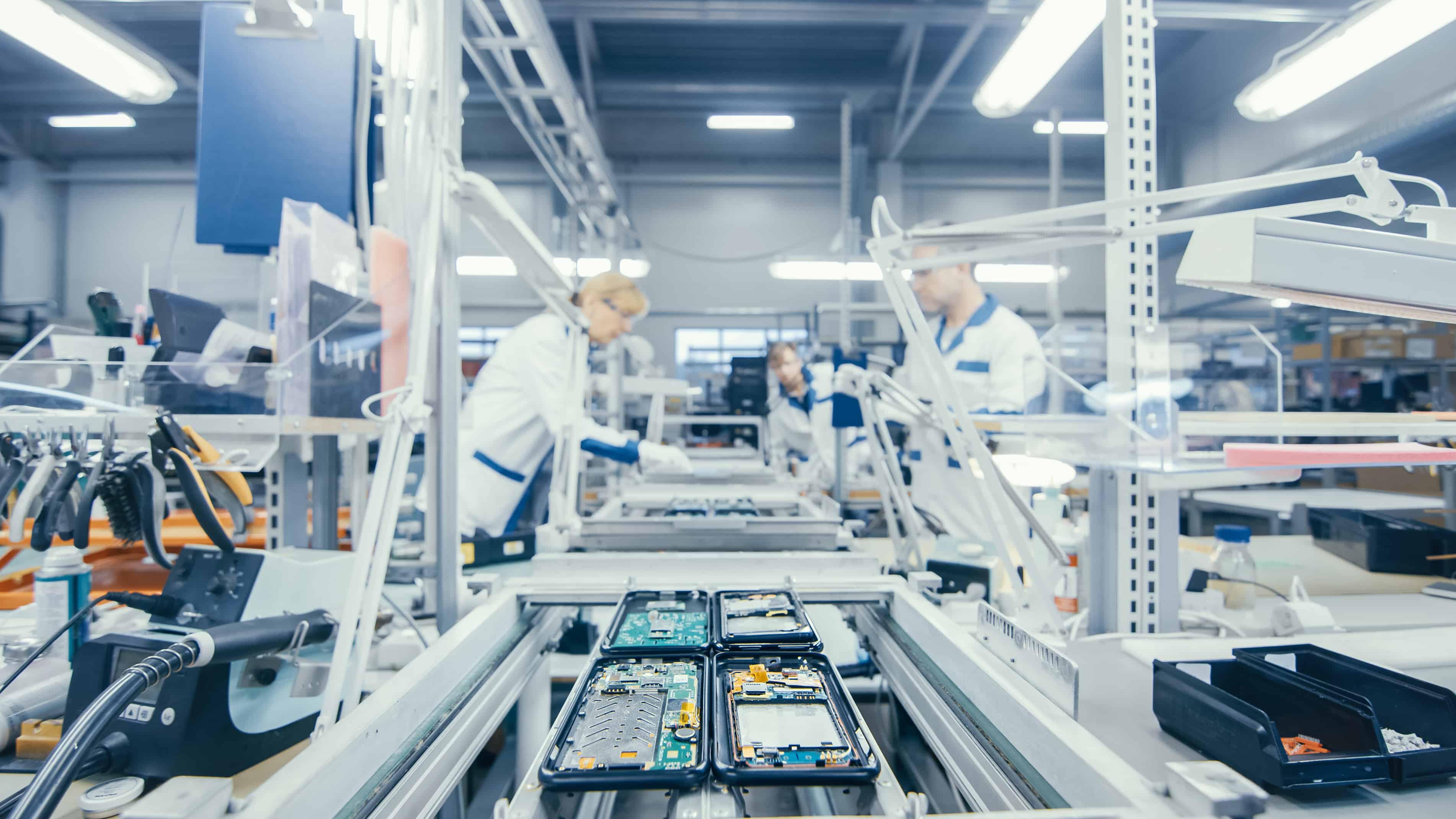

With even more cordless and also wired communication functions being added to clinical electronics tools, and boosted examination by governing bodies, "there is a now more of a 'show me' variable in process development," stated Mc, Clain. bulk materials handling. "Clients don't simply want to hear the process is good. They want to see a statistical sampling plan that shows the process is excellent.For some products, the FDA (or the OEM) requires the monitoring of every part, every piece of manufacturing equipment, and also all driver activity pertaining to the production of a medical device throughout the manufacturing process. Consequently, EMS suppliers require to record manufacturing at a much greater degree than they did simply a couple of years ago.

If an assembly in some way arrives at the wrong step on the manufacturing line, it will instantly be turned down.

His clients vary from start-ups to worldwide manufacturing leaders. He additionally creates a variety of feature articles for local and nationwide magazines and also is the writer of five publications.

Not known Incorrect Statements About Bulk Materials Handling

Manufacturing work are defined as those that develop new products either straight from basic materials or elements. These work are typically in a manufacturing facility, plant or mill but can likewise remain in a home, as long as items, not solutions, are created. For instance, pastry shops, sweet-shop, and also customized dressmakers are considered manufacturing due to the fact that they create products out of elements.Producers are always browsing for more cost-efficient ways of creating their items. That's why, despite the fact that the number of tasks is predicted to decrease, the jobs that remain are likely to be higher paid. They will require education as well as training to obtain the abilities required. That's for 2 factors.

Mc, Kinsey estimated this can virtually triple, to $30 trillion, by 2025. These nations would certainly require 70 percent of worldwide produced goods. Just how will this need adjustment manufacturing jobs? Companies will need to use items particular to the needs of these really diverse markets. Because of this, customer solution tasks will come to be more crucial to suppliers.

Toll manufacturing and also agreement manufacturing are two relatively similar types of supply chain management that are typically misunderstood as well as puzzled. While both of these making choices have distinctive and also clear qualities, their most strategic advantage is their ability to supply customers with useful ways to save both time as well as capital on their line of product development.

The 7-Minute Rule for Bulk Materials Handling

With toll manufacturing, the client is outfitted with the sources to develop their own specialty finishes or documents that Sierra Covering can use in the manufacturing process. Consequently, the consumer has the ability to develop the exact product they imagine, without the time and capital investment bulk materials handling of developing a production procedure.

Over the previous few years, the reported share of services in the economy has actually certainly experienced a sharp boost in most nations. In the United States, for instance, the service field today make up even more than 83% of total work a considerable increase from its share of 60% in 1947. Beyond of the coin is the widely lamented decrease of the manufacturing market.

The 8-Second Trick For Bulk Materials Handling

But two fundamental realities that arise from an easy evaluation people market data recommend that final need is not the only driver of the rise of solutions. First, three industries finance, realty, and also specialist as well as business services make up a huge share of the development of the solution sector.Final intake and net exports account specifically for simply 7% as well as 2% of the market's outcome. An altering input-output structure The specialisation of the professional and also business services sector in intermediate manufacturing, integrated with its strong growth, is reflected in a parallel change in the input-output framework of the economic situation.

The complete use expert and business solutions in the United States economic climate, 19472002 Note: This figure displays, for each and every year, the share of professional and company services in the complete requirements of all products. Number 2 shows the development of the typical forward link for a choice of sectors. Professional as well as company services have actually come to be the industry with the greatest impact on the remainder of the economic climate, surpassing industries with typically high ahead affiliation, such as transportation (industry 65), as well as overshadowing fast-growing industries, such as financing.

For instance, work in the accountancy industry depends upon home demand for accounting services along with demand from companies (bulk materials handling). Changes sought after for intermediate inputs as a result induce a reallocation of labour across sectors. I discover that when last demand is maintained constant with time, the evolution of the input-output structure of the economy alone represents 36% of the complete increase in solution employment as well as 25% of the loss in manufacturing.

The 5-Minute Rule for Bulk Materials Handling

The instinct is simple if a manufacturing firm outsources part of its head offices' solutions, the intermediate use solutions will certainly raise due to the fact that it is most likely that these inputs will be purchased from firms specialising in solutions. Offered the high share of intermediate manufacturing and also the high substitutability that characterises professional and also business solutions, previous study normally identifies the More about the author rise of this industry as a rise in outsourcing.Report this wiki page